Effectiveness Increases Through the Transformer Oil Regeneration Process

Effectiveness Increases Through the Transformer Oil Regeneration Process

Blog Article

Just How Regenerated Transformer Oil Prolongs Transformer Life-span

The function of transformer oil is critical in making sure the dependability and durability of transformers, serving as both an insulator and coolant. Regenerated transformer oil offers an engaging remedy to boost these features by properly eliminating unsafe impurities that compromise performance.

Significance of Transformer Oil

Transformer oil plays an important function in the efficient operation of electric transformers. It mostly acts as a shielding tool, avoiding electric discharges and ensuring that elements run safely under high voltage conditions. The oil's dielectric homes are fundamental to maintaining the honesty of the transformer, as they decrease the danger of failings that might cause devastating cases or pricey downtimes.

Along with its insulating abilities, transformer oil additionally operates as a coolant. As transformers run, they create warmth that needs to be dissipated to avoid getting too hot and subsequent damage. The oil circulates within the transformer, moving and soaking up heat away from crucial parts, thus keeping ideal operating temperature levels.

Moreover, transformer oil serves as a barrier against moisture and contaminants, which can compromise the performance and longevity of the transformer. Its chemical residential properties assist in reducing the effects of acids and other byproducts that might form with time, adding to the total health of the electric system.

Advantages of Regenerated Oil

In addition, regenerated transformer oil has a reduced degree of contaminations, including fragments and pollutants that can break down performance. This pureness not only enhances the oil's thermal conductivity however likewise expands the functional lifespan of transformers by reducing overheating threats. The improved thermal stability of restored oil guarantees consistent performance even under high operating temperatures, which is important for maintaining transformer performance.

Another advantage is its ecological impact. Regrowed oil promotes sustainability by reducing waste and the need for new oil manufacturing, consequently reducing the carbon footprint associated with transformer upkeep. Transformer Oil Regeneration. Furthermore, the durability of regrowed oil translates to reduced maintenance costs in time, as less oil adjustments and less constant equipment downtime are required.

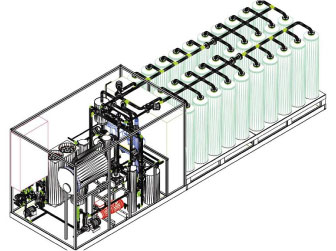

Process of Oil Regeneration

The regeneration of transformer oil includes a systematic procedure made to recover the oil's initial buildings and boost its performance. This process normally starts index with the elimination of the made use of oil from the transformer, which is then subjected to numerous filtration methods.

The primary step in the regeneration procedure is the filtration, where strong impurities such as sludge, dirt, and steel particles are removed. read this post here This is frequently complied with by vacuum cleaner distillation, which helps to eliminate wetness and volatile compounds, thus improving the oil's dielectric toughness.

Influence On Transformer Performance

Restoring the properties of regenerated transformer oil considerably influences the overall efficiency of transformers. Boosted dielectric strength is one of the most critical benefits, as it enables better insulation and reduces the chance of electric breakdown. This enhancement results in a more steady procedure under high voltage problems, ultimately leading to raised performance.

Furthermore, the elimination of impurities and deterioration products during the regeneration procedure minimizes the risk of overheating. Cleaner oil promotes much better warm dissipation, which is essential for maintaining optimum operating temperature levels. Consequently, the thermal efficiency of the transformer is improved, enabling greater lots without jeopardizing integrity.

Furthermore, the chemical security of restored oil makes sure long term functional life. It withstands oxidation and destruction, reducing the regularity of upkeep interventions and oil replacement. This security not just contributes to enhanced efficiency but also lines up with sustainability objectives by lessening waste.

Future of Transformer Upkeep

As innovations in modern technology proceed to improve the landscape of electrical design, the future of transformer maintenance is positioned for significant check that improvement. The combination of clever modern technologies, such as IoT sensors and predictive analytics, enables real-time tracking of transformer wellness, boosting the capability to preemptively attend to issues prior to they escalate into significant failures. This aggressive technique not just maximizes functional performance yet additionally prolongs the lifespan of transformers.

Additionally, the application of expert system (AI) in information evaluation permits for even more accurate fault discovery and diagnosis. By leveraging artificial intelligence formulas, upkeep groups can recognize patterns in operational information that human analysts may forget, resulting in even more enlightened decision-making.

Furthermore, the adoption of green methods, including using regenerated transformer oil, is readied to redefine upkeep protocols. This lasting technique not only minimizes ecological impact but additionally enhances the overall wellness of the transformer.

Last but not least, the change in the direction of automation in upkeep procedures is anticipated to simplify operations, lower downtime, and reduced costs. As these developments remain to advance, the future of transformer maintenance will most certainly come to be much more reliable, trusted, and sustainable, ensuring the honesty of crucial electrical infrastructure.

Conclusion

The use of regenerated transformer oil dramatically enhances the functional longevity of transformers. Inevitably, the adoption of restored oil stands for a pivotal development in transformer maintenance, ensuring optimal efficiency and sustainability in the monitoring of electrical framework.

The duty of transformer oil is crucial in ensuring the integrity and durability of transformers, serving as both an insulator and coolant.Transformer oil plays an important function in the effective procedure of electric transformers. Regenerated oil advertises sustainability by reducing waste and the requirement for new oil manufacturing, consequently lowering the carbon impact associated with transformer maintenance.Bring back the buildings of regenerated transformer oil dramatically influences the overall efficiency of transformers.The utilization of regenerated transformer oil substantially improves the operational durability of transformers.

Report this page